In the world of working drawings, schedules and specification writing are structured methods for the presentation of comprehensive notes or details of materials, architectural components (such as doors and windows), and various equipment within a drawing. These are typical organized in tabular form and are often accompanied by pictorial schedules for additional clarity. The primary objective behind integrating schedules into a compilation of construction documents is to communicate clearly regarding the location, dimensions, materials, and specifications of doors, windows, roofing materials, equipment, plumbing, electrical fixtures and other building components.

The careful execution of schedules serves a crucial role in preventing drawings from becoming too crowded by excessive textual information or annotations. Schedules benefit not only the drafter but also prove instrumental for architects, engineers, contractors, and on-site personnel. Schedules provide information on the product name, model number, size, quantity, rough opening size, material, color or finish of building components.

This post is designed to provide insights into the interpreting of tabulated information present on working drawings. It is important to know that schedules and specifications provide explicit details pertaining to building elements, whereas drawings provide the dimensions, location and placement of the elements in question.

Types of Schedules in Construction

Schedules are not only used by architects. They are produced by structural engineers, mechanical and electrical engineers, and contractors. Schedules are generally organized in a drawing set such that they are near the discipline to which they are related. Here are some types of schedules produced as part of construction documents:

- Door Schedules

- Window Schedules

- Finishing Schedules (wall, floor and ceiling finish)

- Lightning Fixture Schedules

- Electrical Fixture Schedules

- HVAC Schedules

- Plumbing Schedules

- Furniture Schedules

The list does not stop there, as schedules can be produced for almost every building component e.g., roof, lintels, columns, beams, appliances, etc. In summary, schedules serve as a vital part of drawings as they give a breakdown of all necessary elements in construction.

As an architect, there are certain schedules which fall under your line of work. The major types are door schedules, window schedules, and finishing schedules. However, you may also do other schedules for relatively smaller projects. Let’s take a look at the major type of schedules.

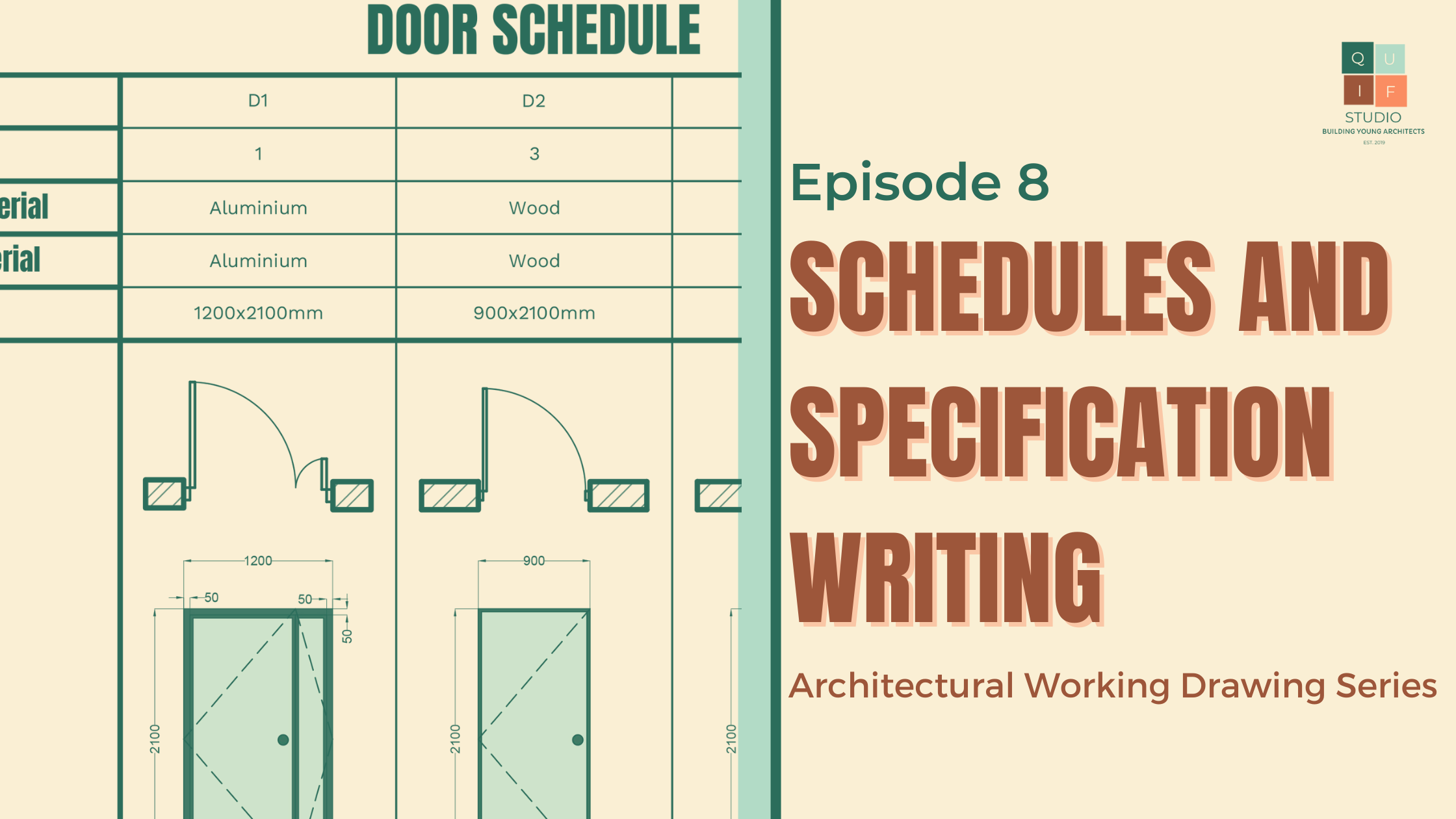

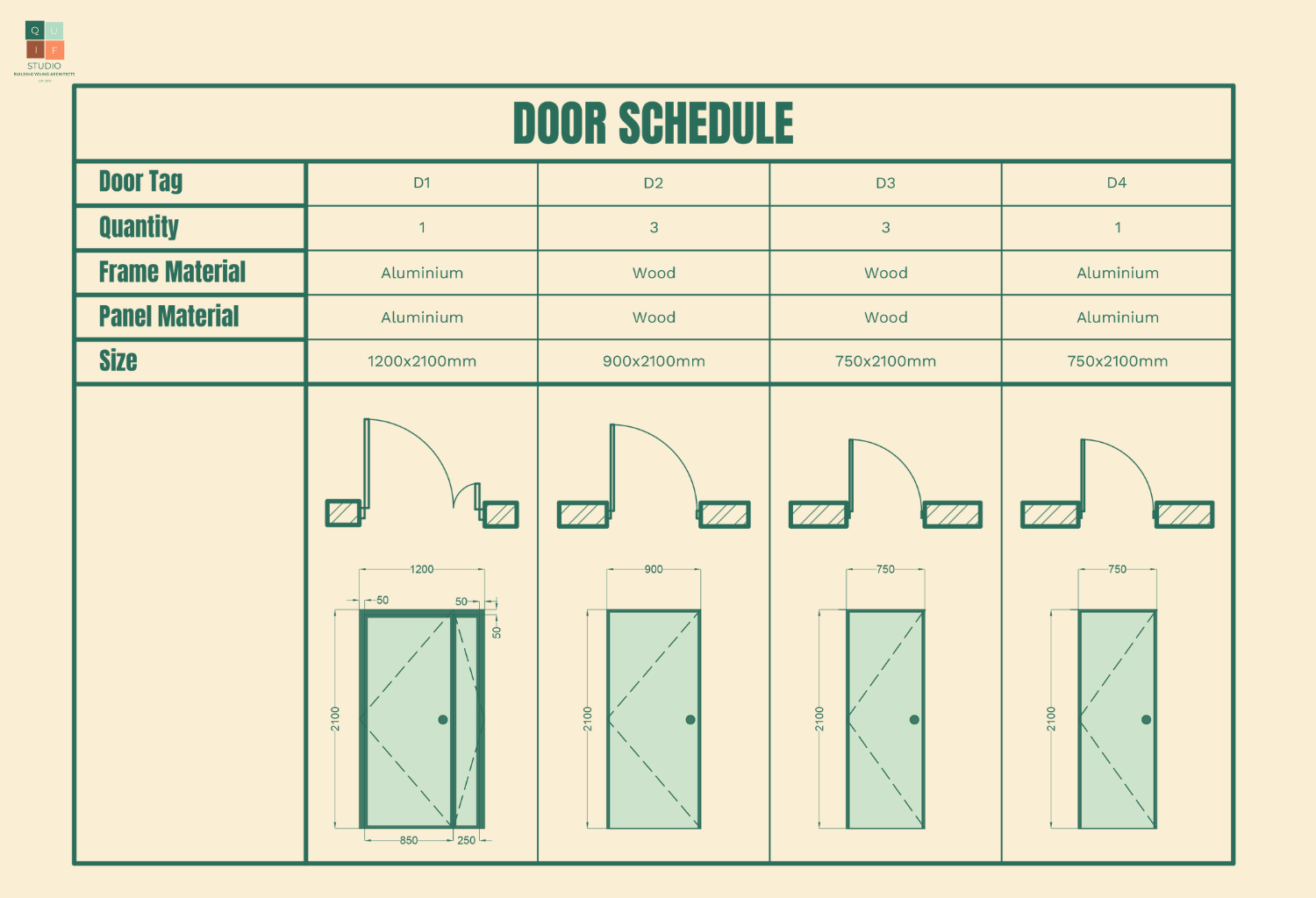

Door Schedules

Door schedules typically indicate the tag number, model, quantity, size, thickness, type, material, function, frame material, fire rating, and remarks. Sometimes tabulated door schedules are accompanied by graphical representations in pictorial form with floor plan views and elevational views of the door to facilitate identification. Door schedules may include information regarding glazing and louvers if appropriate.

Window Schedules

Similar to a door schedule, a window schedule provides an organized presentation of the relevant window features. The pictorial form of the window in the schedule should provide information on the fixed and operational parts of the window and indicating the hinge location. Window schedules provides information of the tag number, quantity, type, model, manufacturer, size, rough opening, materials, glazing, and finish. An additional column for remarks/notes can be added to the table.

Finishing Schedule

A finishing schedule specifies the interior finishing for each space in the building. The schedule provides information for the wall finish, floor finish, and ceiling finish. The finishing schedule should account for every space in a building including entry ways, hallways, etc. In finishing schedules, it is necessary to assign a room number to every space. This is usually done with a number system. An example is “101”. The first “1” indicates the floor level, which starts from the ground floor, while “01” indicates the number of the space.

In assigning wall finishing, certain projects may have different wall finishing within the same space. To cater for this, each wall is divided to north, south, east and west wall.

Schedules and specifications play a crucial role. These organized tables are not just about preventing clutter; they are tools for effective communication. Each schedule tells a unique story, detailing materials and dimensions. Remember, schedules go beyond doors and windows; they touch every aspect of construction, guiding the building’s creation. So, embrace the simplicity of tables, turning architectural drawings into harmonious structures that stand the test of time. In these details, you find the true artistry of architectural creation.